After the plywood is on the walls and the roof, we were ready to apply the water barrier that keeps rain and snow from rotting the wood frame of the house. We're using metal roofing so we applied 30# felt tar paper to the roof. You cut your the length that you need then staple it to the ply wood underneath. Start with the bottom layer of paper and work up toward the peak of the roof overlapping the paper by at least 4 inches. We covered the peak of the roof in this picture since it was going to rain heavily for the following three days, but we might cut that out when we install the metal roofing for ventilation.

Most people you Tyvek, a plastic house wrap, or something similar to cover the walls. However, since we're planning to use rough cut vertical slabs as our siding instead of overlapping horizontal siding, I thought it would be prudent to use something a little more heavy duty. We used adhesive, self healing tar paper and installed it in the same way as the roof, starting at the bottom and working up, overlapping and using a hammer tacker to secure it. Royce is calling it the ninja house :)

The Roeswoods build a 224 sq ft home on wheels. Simple. Vibrant. Living big with a tiny budget and a tiny footprint.

Thursday, July 31, 2014

Monday, July 21, 2014

The Walls

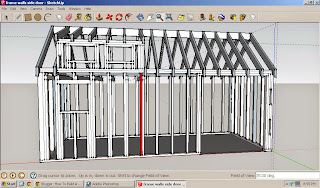

Day 3 of the build found us putting up walls already! Can you believe it?! Helping hands and a lot of know how really go a long way. We started with the end walls.

After that we added a second top plate for stability and anchored the side walls using 5/8" bolts and self locking nuts. Under the door frame we drilled a hole to drop the head of the bolt down into the 2x4.

The floor made a really nice work space on which to layout our walls.

We used 16" centers for the studs. (For those of you who don't know, walls need support studs at regular intervals, usually 16 or 20 inches. You center the studs over each 16 inch mark. That's call 16" on center.) Our rear end wall has no windows so we started there. We built the six wall pieces that do not go over the wheel wells before putting them up on the trailer. Two of the side wall sections had extra long top plates to extend over the wheel wells and connect to the front sections.

Dad, and my wonderful friend Dana bracing one of the side walls.

We check often for plumb (straight up and down) and squareness (90 degree angles) when putting up the walls and we used a lot of bracing to keep them that way.

Once we had the wall pieces up, we built a bottom plate around the wheel wells and inserted studs to brace those sections of the walls.

After that we added a second top plate for stability and anchored the side walls using 5/8" bolts and self locking nuts. Under the door frame we drilled a hole to drop the head of the bolt down into the 2x4.

Door frame.

This nut is not fully tightened.

Saturday, July 19, 2014

The Floor

After sealing the floor of the trailer with aluminum sheeting we were ready to build the floor. We used rigid foam insulation set into the trailer frame. The insulation is two feet wide and it almost fit right into the channels. One of the channels was wide enough to pound it in after I cut of the 1/4 inch tongue on one side of the insulation with a razor blade. The other two channels require some skill-saw trimming. We used more silicone caulking in the places were the insulation was not tight to the frame to prevent airflow around the foam. Airflow around rigid foam sort of ruins its insulation value.

Next we laid some 6 mil plastic over the insulation to provide a vapor barrier from the house. Over the vapor barrier we installed 5/8" tongue and groove plywood sub-floor. We used the skill-saw to cut it to fit the width as well as fit around the wheel wells.

My brother likes to photograph me while I'm eating.

Go floor!! We used more self tapping screws to attache the plywood directly to the frame of the trailer. We actually drilled holes first since we kept breaking screws and bits. I couldn't decide under pressure what I wanted to do about the floor so we just left the sub-floor as it is here and I will add the finish floor in later.

The Trailer

I'm quite behind, but I've been soooo busy the past 5 weeks. Here's the first of many to bring you all up to speed.

We finally (after many delays and worried emails) picked up our trailer.

That's my dad rockin' the pony tail! I ordered my aluminum sheeting from a fabrication shop and they cut it to size for us. Many tiny home builders will cover the entire top of the trailer bed with metal sheeting because they then build a floor frame on top of it. This has never made sense to me since the trailer already has a frame and if you put your insulation down into the frame of the trailer it saves you 3.5 inches of head space!

We did have to do a little bit of finagling to fit the sheeting in because I ordered it before we actually had the trailer. DO NOT DO THIS!!! The only reason I did that was because our trailer was so late coming in and I wanted to save build time because my dad only had 10 days to work with me. We were lucky that the aluminum fit the way it did because even though I called the manufacturer to get the the sizes I needed for the metal, when we actually got it we found some measurements that differed from what I got over the phone. It would have been much safer to just take the measurements I needed myself to make sure. We had to install some angle iron on the edge of one of the channels to take up extra space as well as on the front and back to hold it up on the edges.

We used self tapping screws to attach the angle iron and the sheeting to the trailer frame. I destroyed several drill bits in the process. Screwing through metal is not so easy. Then we used silicone calking around all the edges of the aluminum sheeting to seal the insulation off from any ground water that would attempt to make an entrance. Whew... that only took two days.

We finally (after many delays and worried emails) picked up our trailer.

Isn't it beautiful!

We ordered our 20' trailer from Tiny Home Builders. We opted for the dropped axle which provides 2-3 extra inches of head space. I didn't know until I received the trailer that a dropped axle also decreases the width of the trailer bed from 7' 6" to 7' 3". If I had known, I probably would have for forgone the dropped axles which cost extra anyway. However, the trailer is well made and Dan at Tiny Home Builders jumped through a few hoops for us to make sure we would get our trailer by the time my dad flew in from Alaska to help with the build.

We spent a long time making sure the bed of the trailer was level so that the house would be level as we built upon it. You might notice in the picture above that we'd already put in the aluminum sheeting we installed to protect our rigid foam insulation from road water. Here's a pic of that installation.

We did have to do a little bit of finagling to fit the sheeting in because I ordered it before we actually had the trailer. DO NOT DO THIS!!! The only reason I did that was because our trailer was so late coming in and I wanted to save build time because my dad only had 10 days to work with me. We were lucky that the aluminum fit the way it did because even though I called the manufacturer to get the the sizes I needed for the metal, when we actually got it we found some measurements that differed from what I got over the phone. It would have been much safer to just take the measurements I needed myself to make sure. We had to install some angle iron on the edge of one of the channels to take up extra space as well as on the front and back to hold it up on the edges.

Wednesday, June 4, 2014

A Healthful, Organized Kitchen

Food is a perpetual stressor in my life. I didn't grow up gardening so I don't really know how (yet) to grow my own food as I'd like to. I am also a reluctant cook. Much of the food in the grocery store looks like poison to me, covered in pesticides and highly processed sugar, corn, soy, and bleached wheat. These things plus the considerations of a budget have often left me feeling frustrated, confused, and hungry. Over the past few years I've made some small gains. I've connected with some local farms to get their fresh produce. I still don't know how to cook it, but I sure like to eat it! I can follow a recipe when I get the motivation to look one up. I've found some books on health and nutrition that align with my values and goals. One of the reasons I wanted to build a tiny house was to have a kitchen that would be more in line with how I want to eat and help us transition to a healthier, more connected food lifestyle. And now, I've designed a kitchen for our tiny house specifically to organize fresh, natural, and healthy food.

In the house design, you can see that I have planned a kitchen with a large sink and a small range.

In the house design, you can see that I have planned a kitchen with a large sink and a small range.

This is in line with our needs as I don't cook a lot of food, and I don't do it often. The other day though, I was worrying about what we would eat since my kitchen does not have a refrigerator! I planned it this way because I want to force myself to eat more fresh. (We will install one under the range, but I plan to use it more as a cooler or ice box. We definitely won't have a door full of condiments that sit there for years.) However, I didn't have a clear idea of how to feed myself or my husband this way.

With the help of some research on an anti-inflammatory diet I created a comprehensive list of the foods I wanted to have in my kitchen. Click here to see the google spreadsheet of my foods. With that information I set out to design a pantry to store it in a space saving way that is easy to use. This is what I came up with.

I'm very pleased. Some of the shelves slide out for easy access. The top has 8 quart sized mason jars with the lids attached to a piece that slides out so the jars hang down and even the ones in the back are easily accessible. The spice drawer will be built specifically to hold spice bottles so they're not rolling around or getting in the way. This is the perfect pantry to make our tiny kitchen organized and usable.

You may have noticed another little design on the left for a dish cabinet. I saw this picture and thought, Genius!

So I designed one that would satisfy our dishes. Now, I am at ease in the knowledge that our kitchen with be tidy and useful. It will give me the feeling of organization that I need to transition to a new food lifestyle.

Saturday, April 26, 2014

A Little Re-design

I've been thinking about the ladder problem in our house. As much as I could climb up and down a ladder to get to the sleeping loft, I don't really want to. However, I've been very attached to the layout of our living area and I played around a couple times with putting a staircase in, but it just didn't work for me. A couple days ago I thought about putting the stair case at the back of the house instead of the front. When I Sketched it up, I found myself totally in love with the results.

These stairs (which I found instructions for here) also provide lots of storage space which my previous design was seriously lacking. I really like the way it looks and the flow it provides in the house.

It even provides comfortable orientation of and access to the bed, something that I was struggling with before.

I did this sketch on a 7 foot wide trailer since I've been having trouble finding access to an 8' one and am playing around with settling for less. I'd rather not, but I think we'd be okay if that's what we need to do.

Thursday, April 17, 2014

Heating and Cooking

Heat and energy are hot topics in the green building sphere. If I were building a house on the ground I would build it to use passive solar heat with thermal mass and local, natural building materials for sure. However, given the extremely limited space and weight restrictions associated with building on a trailer, our green building options are correspondingly limited. Today I want to talk about heating our home.

As far as I can tell, our heating options are electric, propane, gas, or wood. Since we'll be off the grid using solar panels, I don't want to rely on them to heat the house in the winter. Propane and gas have pros for lots of people, but for me, I really don't want to be reliant on fossil fuels that use environmentally destructive extraction methods. The whole point of this house project is to reduce our compliance with the grid and remove as many petrochemical products from our lives as possible. I grew up using wood burning heat and am very comfortable and enchanted with using wood stoves.

There are a couple of beautiful and adorable marine wood stoves available.

This one is so cute, but it takes at least 6 months to be delivered because they custom make each one.

Right now, this is the one at the top of my list. I'm excited about it and it's actually cheaper than the Dickson's Marine propane stoves.

As far as cooking goes, I've decided to omit an oven. They are big and I don't bake that much anyway. If I need to bake anything I'll have to do it in my dutch oven. Today I discovered that there are alcohol fueled cook stoves! Here is an article I found useful about them. Aside from ethanol not being a petrochemical, I really enjoy that it isn't explosive. Also, if I get really ambitious I can make it myself. The Origo 3000 double burner stove is only $350. In the summer I'll try to do most of the cooking out doors on a grille or fire pit. While ethanol or grain alcohol is significantly more expensive per gallon than propane, the pros significantly outweigh the cons at this point.

I really enjoyed reading this blog post and the quote she posted from Ann Holley, “It’s really important to have all of your utilities before you begin building,” she said, “so that you know the exact dimensions and what you’ll need to do to install them. It really helps to plan that out ahead of time.” With that in mind, we'll be ordering our utilities quite soon. I just want to sleep on it one more night.

As far as I can tell, our heating options are electric, propane, gas, or wood. Since we'll be off the grid using solar panels, I don't want to rely on them to heat the house in the winter. Propane and gas have pros for lots of people, but for me, I really don't want to be reliant on fossil fuels that use environmentally destructive extraction methods. The whole point of this house project is to reduce our compliance with the grid and remove as many petrochemical products from our lives as possible. I grew up using wood burning heat and am very comfortable and enchanted with using wood stoves.

There are a couple of beautiful and adorable marine wood stoves available.

This one is so cute, but it takes at least 6 months to be delivered because they custom make each one.

Right now, this is the one at the top of my list. I'm excited about it and it's actually cheaper than the Dickson's Marine propane stoves.

As far as cooking goes, I've decided to omit an oven. They are big and I don't bake that much anyway. If I need to bake anything I'll have to do it in my dutch oven. Today I discovered that there are alcohol fueled cook stoves! Here is an article I found useful about them. Aside from ethanol not being a petrochemical, I really enjoy that it isn't explosive. Also, if I get really ambitious I can make it myself. The Origo 3000 double burner stove is only $350. In the summer I'll try to do most of the cooking out doors on a grille or fire pit. While ethanol or grain alcohol is significantly more expensive per gallon than propane, the pros significantly outweigh the cons at this point.

I really enjoyed reading this blog post and the quote she posted from Ann Holley, “It’s really important to have all of your utilities before you begin building,” she said, “so that you know the exact dimensions and what you’ll need to do to install them. It really helps to plan that out ahead of time.” With that in mind, we'll be ordering our utilities quite soon. I just want to sleep on it one more night.

Monday, April 7, 2014

The Great Insulation Debate

I went through quite a journey this morning thinking about how to insulate our tiny house. For the last year or so, I've been planning to use either recycled denim or wool insulation. They are natural, non-toxic products that are safe to install. But, I've also been talking with builders I know to ask their opinions. Specifically I was asking about how to insulate the floor in a way that minimizes the height inches that could otherwise be used as valuable head space. My dad has been brainstorming for me and we considered laying blue board on the deck of the trailer and laying the floor right on top of it. This would take about 2 inches. Yes! Saved 2"! Then we thought about putting the blue board under the deck. Saves another 2". Then he suggested that it might be better to use spray polyurethane foam (SPF) under the deck as it would completely seal the floor of the deck.

Hmm... I'll have to think about that. Yesterday I asked my uncle his opinion as he is a building contractor. He suggested that we use the foam not only in the floor but in the walls and ceiling as well. It would provide an R-value (this is the unit of measurement for how well an insulation prevents temperature transfer) equal to a standard house with just an inch an a half of foam. It would also contribute greatly to the stability of the structure because when it hardens it adheres to the surfaces it's in contact with and would basically make the floor, walls, and ceiling one continuous solid mass. This seemed highly desirable to me. However, I'm also highly concerned with toxicity in the home.

So this morning I went on a google quest to find out more about insulation. I found this website developed by the EPA to help people use SPF safely http://www.spraypolyurethane.org/. Then I discovered that Ecovative is developing an insultaion made out of mushrooms!!! http://www.treehugger.com/green-architecture/tiny-house-mostly-made-mushrooms.html, http://www.ecovativedesign.com/products-and-applications/insulation/. I want it. Unfortunately it is not available yet. Bah! Then I discovered this article which put me pretty solidly back on team denim. http://www.treehugger.com/green-architecture/whats-the-greenest-insulation.html . Apart from the dangers associated with installing the SPF which include inducing extreme chemical sensitivity, this quote reminded me of a lot of other things that are important to me:

I guess we'll just have to use a lot of good screws to ensure the structure is solid.

Hmm... I'll have to think about that. Yesterday I asked my uncle his opinion as he is a building contractor. He suggested that we use the foam not only in the floor but in the walls and ceiling as well. It would provide an R-value (this is the unit of measurement for how well an insulation prevents temperature transfer) equal to a standard house with just an inch an a half of foam. It would also contribute greatly to the stability of the structure because when it hardens it adheres to the surfaces it's in contact with and would basically make the floor, walls, and ceiling one continuous solid mass. This seemed highly desirable to me. However, I'm also highly concerned with toxicity in the home.

So this morning I went on a google quest to find out more about insulation. I found this website developed by the EPA to help people use SPF safely http://www.spraypolyurethane.org/. Then I discovered that Ecovative is developing an insultaion made out of mushrooms!!! http://www.treehugger.com/green-architecture/tiny-house-mostly-made-mushrooms.html, http://www.ecovativedesign.com/products-and-applications/insulation/. I want it. Unfortunately it is not available yet. Bah! Then I discovered this article which put me pretty solidly back on team denim. http://www.treehugger.com/green-architecture/whats-the-greenest-insulation.html . Apart from the dangers associated with installing the SPF which include inducing extreme chemical sensitivity, this quote reminded me of a lot of other things that are important to me:

...there are many legitimate arguments against the use of a petrochemical, high-embodied energy, non-renewable, non-recyclable, non-permeable, difficult to remove, problematic for renovation, and expensive insulating material.

I guess we'll just have to use a lot of good screws to ensure the structure is solid.

Friday, April 4, 2014

Designing Your Tiny House

When sketching houses, I just draw whatever I'm thinking about, but when designing houses, I usually start with a floor plan. It's important to know where you're going to put things and that they will fit before you spend a lot of time drawing or building them in. My original floor plan looks like this:

A floor plan allows you to see traffic paths between spaces, to play with the location of rooms and furniture, and to notice how certain spaces may interact with each other. Tiny houses in particular require a well thought-out floor plan. You need to know where you'll be spending time, what you require of those spaces, and the simplest, most practical way to organize them. If you are unsure of how to begin, a bubble chart is a great place to start.

Determine your activities and give a name to the space in which you'd like to do them. You'll probably sleep in a bed for example. Allow the size of each bubble to reflect the amount of time you expect to spend there relative to the other bubbles. Then rearrange the bubbles so that activities you often switch between are close together. You can also make choices about spaces you'd like removed from sight; for example, if you want to have a children's play area, you can decide if you want it to be under your nose or out of your hair. In my plan, I know I want food and family time to be close together and easy to access. I've put all the social space out front. I put the bathroom and Royce's office under the loft because they are private spaces and should be removed from the notice and distraction of the social spaces. There's also a space back there for the batteries and any other work stuff that doesn't need constant attention. The bubble chart allows you to get a feel for how your house should flow. Then you can fill in the details with a floor plan. Then if you want to you can build up the flow plan in SketchUp to see how the house might actually look! Having a plan is so important. Having the image in mind is so motivating!

A floor plan allows you to see traffic paths between spaces, to play with the location of rooms and furniture, and to notice how certain spaces may interact with each other. Tiny houses in particular require a well thought-out floor plan. You need to know where you'll be spending time, what you require of those spaces, and the simplest, most practical way to organize them. If you are unsure of how to begin, a bubble chart is a great place to start.

Determine your activities and give a name to the space in which you'd like to do them. You'll probably sleep in a bed for example. Allow the size of each bubble to reflect the amount of time you expect to spend there relative to the other bubbles. Then rearrange the bubbles so that activities you often switch between are close together. You can also make choices about spaces you'd like removed from sight; for example, if you want to have a children's play area, you can decide if you want it to be under your nose or out of your hair. In my plan, I know I want food and family time to be close together and easy to access. I've put all the social space out front. I put the bathroom and Royce's office under the loft because they are private spaces and should be removed from the notice and distraction of the social spaces. There's also a space back there for the batteries and any other work stuff that doesn't need constant attention. The bubble chart allows you to get a feel for how your house should flow. Then you can fill in the details with a floor plan. Then if you want to you can build up the flow plan in SketchUp to see how the house might actually look! Having a plan is so important. Having the image in mind is so motivating!

Thursday, April 3, 2014

The Height Problem

If you intend to be able to move your house on the road, it cannot exceed 13 feet 6 inches tall. We intend to put a sleeping loft in our house, and since the house is built on a trailer that means the potential head space on both levels is very limited and every inch is precious. Since we don't have our trailer yet, I'm not exactly sure how high the floor is going to be. For preliminary planning purposes I've been allowing 2 ft for it. This first problem I had was that I'd really like to put a sliding glass door on the long wall:

These doors basically come in standard dimensions and particularly since I'm planning on picking one up for free on craigslist I can count on it being 80 inches tall. If I build the sleeping loft the way you normally do, with the joists sitting on top of the top plate of the walls (like this is you don't know what that means)

that means we'll only have about 3 feet between the floor of the loft and the highest point of the roof. Also, our bed is 1 foot tall. It was starting to look more like a crawl space than a sleeping loft and I really didn't want to feel like I was sleeping in a coffin. So my solution to this is to frame the loft into the wall rather than on top of it. It looks like this.

This allows me to lower the loft without losing any height on the walls. The other thing I decided to do was to add a dormer in the loft.

This will give us a little extra head space in the loft. A little more feeling of openness. Anyway, this is what I've come up with so far. I'm making this up as I go along, so I'll let you know if it works out! This blog gives good advise about how to customize your trailer to maximize head space: http://tinyhousebuild.com/gain-head-space-tiny-house-design/

Up til now

Royce (my husband) and I have been talking about building a tiny house on wheels for over a year. At first we couldn't decide whether we wanted to spend our money on a trip to the UK to walk the Coast to Coast trail or on a tiny house. A couple months ago we decided to build the house and to do by the time our lease is up in the middle of September.

I've been oogling pictures of tiny houses for a long time so I had lots of ideas about what I might want my house to look like. About a year ago I started reading books about drafting and architecture. I started practicing drawing and designing houses of various sizes and materials. I discovered Google SketchUp in January and spent a couple of days developing houses on it. (SO FUN!) Ultimately I decided that this is the design I like the best:

Luckily for me, Royce is perfectly happy to let me steer on designing at this stage. Then we decided on a budget for our house, $10,000. This is for everything including the photovoltaic system. We plan to be completely off the grid.

I'm fortunate to know several handy people including my dad who builds custom full scribe log cabins in Alaska. I've been reading his books and picking his brain, asking him questions, and solving problems for the last couple months. I'll go into some of these in detail later.

Where we are now: I'm looking to have a trailer by May. I'm collecting building materials for free from craigslist. Considering that we have less than 6 months for finish it and move in, I'm eager to get started!

A Good Suggestion

I was having an extended tea time with a dear friend today. We were talking about stuff and things including my husband and my current mission to build ourselves a tiny house on wheels and my ambition to become a Landscape Architect. She suggested wisely that I use a blog to document our progress and that I could use it later as a component in my portfolio. What a smart girl.

Subscribe to:

Posts (Atom)